Depletion

What is Depletion?

Depletion is a reduction in reservoir pressure as a result of producing hydrocarbons. The reduction of pore pressure influences the fracture pressure and formation strength. The rate of the depletion can have a high degree of variability across a reservoir along with the affect that depletion has on the fracture pressure. Furthermore, there can be pockets that still contain the initial pore pressure mixed together with depleted pore pressure areas.

Why is Depletion a Challenge?

The main challenges stem from the heterogeneous nature of depleted zones: the combination of a reduction in the fracture pressure and the uncertainty in pore pressure. The initial or higher pore pressures cannot be completely ruled out, commonly pockets of initial pressure are present, where depletion has occurred, while the reduced fracture pressure and formation strength is prevalent throughout most of the zone.

This can create a narrow operating window and increases the potential for going on losses or going underbalanced while drilling in depleted zones. In addition there are lost circulation and stability challenges in drilling overburden as the depletion in the reservoir formations below have changed the stress regime in the overburden. The challenges of lost circulation can be compounded if attempting to drill through the overburden and depleted reservoir together in a single section.

What Are Your Options?

- Drill depleted zones with a mud density high enough to balance the initial or highest possible pore pressure. This means that the risk of lost circulation is increased as the fracture pressure is lower in depleted zones. A higher mud density can also be used as a contingency in case a pocket of higher pressure is encountered. This may reduce the lost circulation risk, but will increase the risk of a well control incident.

- If the plan is to drill through the overburden and into a depleted reservoir in a single section, an option is to set additional casings to avoid drilling overburden and reservoir in same section. This can enable the use of different mud densities for each section that are better suited to deal with the lost circulation and stability challenges for each section.

- Drill with an Managed Pressure Drilling (MPD) system. A MPD system enables you to control the annulus pressure more precisely and to drill with a Constant Bottom Hole Pressure approach reducing the likelihood of taking losses or having an influx.

How EC-Drill® Can Help You With Depletion

The EC-Drill® Controlled Mud Level is a MPD system that enables you to quickly adjust the annular pressure by changing the fluid level in the riser.

With EC-Drill® the initial annular pressure can start out above the highest potential pore pressure while drilling into a depleted zone. When encountering depleted zones with a lower fracture pressure the riser fluid level can be lowered to match the new operational window caused by depletion. At any time the annular pressure can be increase back to the initial point by raising the riser fluid level.

A Constant Bottom Hole Pressure can be maintained by adjusting the riser fluid level between static and dynamic conditions, and the annular pressure can be adjusted any time as conditions dictate.

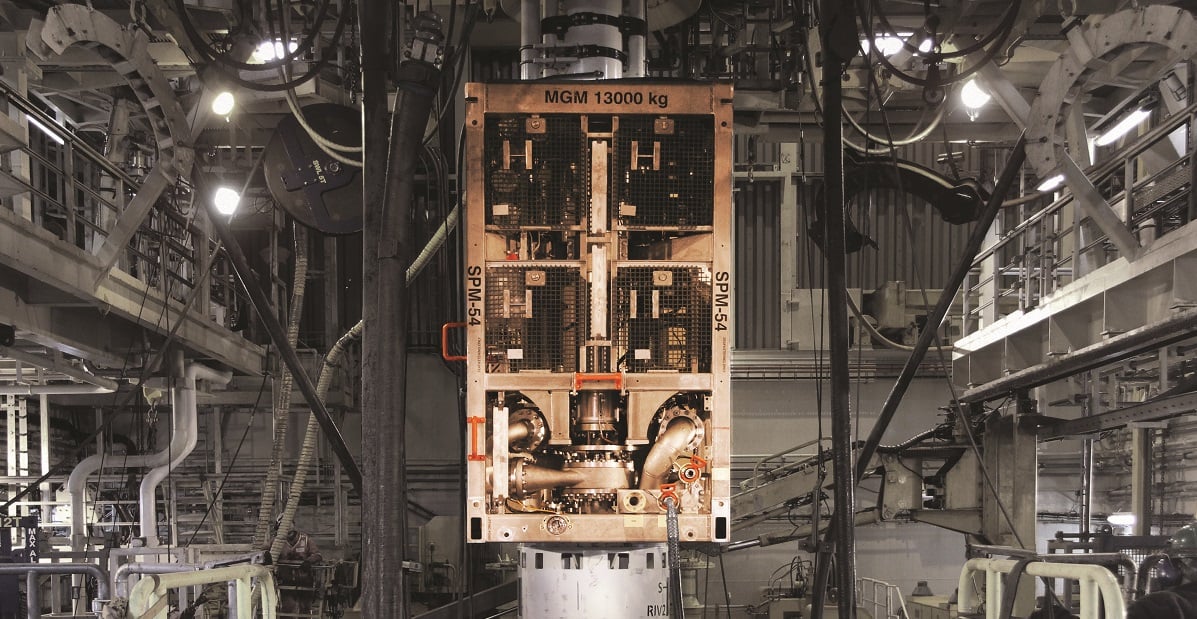

EC-Drill®

EC-Drill® is a Controlled Mud Level (CML) technology that allows manipulation of bottom hole pressure (BHP) while drilling a well. The system controls the BHP by adjusting the fluid level in the marine drilling riser, and thereby the hydrostatic pressure applied.