Managed Pressure Drilling

What is Managed Pressure Drilling?

Managed Pressure Drilling (MPD) is a drilling process used to precisely control the annular pressure profile throughout the wellbore. Additional technology and equipment systems are incorporated into conventional drilling systems to achieve the ability to adjust and control the annual pressure profiles downhole.

MPD allows more accurate bottom hole pressure control, resulting in fewer pressure fluctuations and improved control of the well. There are three main MPD categories and several MPD techniques. The shared application for the different MPD methods is the ability to control and adjust the annular pressure profile.

Challenges associated with MPD

MPD can be a great tool for solving drilling challenges, however it is often accompanied by additional cost, operational time and complexity. The additional costs are from rig integration and added equipment as well as the extra operational time or “flat-time” during operations. The “flat-time” is caused by extra operations that are required with MPD systems, such as displacements of drilling fluid or running and retrieving downhole tools, and limitations on drilling parameters.

Some MPD systems have operational limitations, for example one system may cause uneven annulus pressure profiles while another cannot be used when no pipe in the well or is not flexible enough to be used outside of the planned drilling operations. These operational challenges and additional “flat-time” can add substantially to the upfront costs associated with rig integration.

What Are Your Options?

- The most common MPD systems are Continuous Circulation System, Surface Back Pressure, and Controlled Mud Level. All the three methods have their respective advantages and limitations.

- Continuous Circulation System (CCS) offers the most uniform pressure profiles across the annulus but it is limited in use and when not circulating at planned drilling rate.

- Surface Back Pressure (SBP) is traditionally the most common MPD system. It can adjust the annular pressure faster than the other methods and has the ability to circulate out small influx volumes. SBP is the most expensive and has the largest footprint of all the MPD systems. SBP normally relies on using an underbalanced drilling fluid density during drilling and increasing pressure by choking back the well. As a result additional operational time is required for displacements of drilling fluid between the drilling and tripping, in addition to the time spent running & retrieving bearings and sealing elements.

- Controlled Mud Level (CML) is the most flexible of the MPD technologies and is applicable during the entire well construction process, across drilling, tripping, cementing, and completion operations. CML requires a smaller footprint and lower rig integration cost compared to SBP. The operational “flat-time” is limited for CML operations and significantly less than SBP. CML relies on conventional barrier principles by using an overbalanced drilling fluid density and conventional well control.

How EC-Drill® Helps You With Managed Pressure Drilling

EC-Drill® is a Controlled Mud Level technology. It gives you greater control of your bottom hole pressure as well as safety-enhancing features such as rapid gain and loss detection, plus the means to act swiftly to changes in the well. EC-Drill® is ideal for Narrow Operating Windows, accurate monitoring of the well for gains and losses, managing lost circulation, and quickly responding to changes in the well by adjusting bottom hole pressure for drilling, cementing, and completion operations.

An overbalanced mud weight is used with controlled mud level enabling conventional drilling to be returned to at any time. The ability to adjust the Riser Level provides trip margin and eliminate the need for displacing the well between operations.

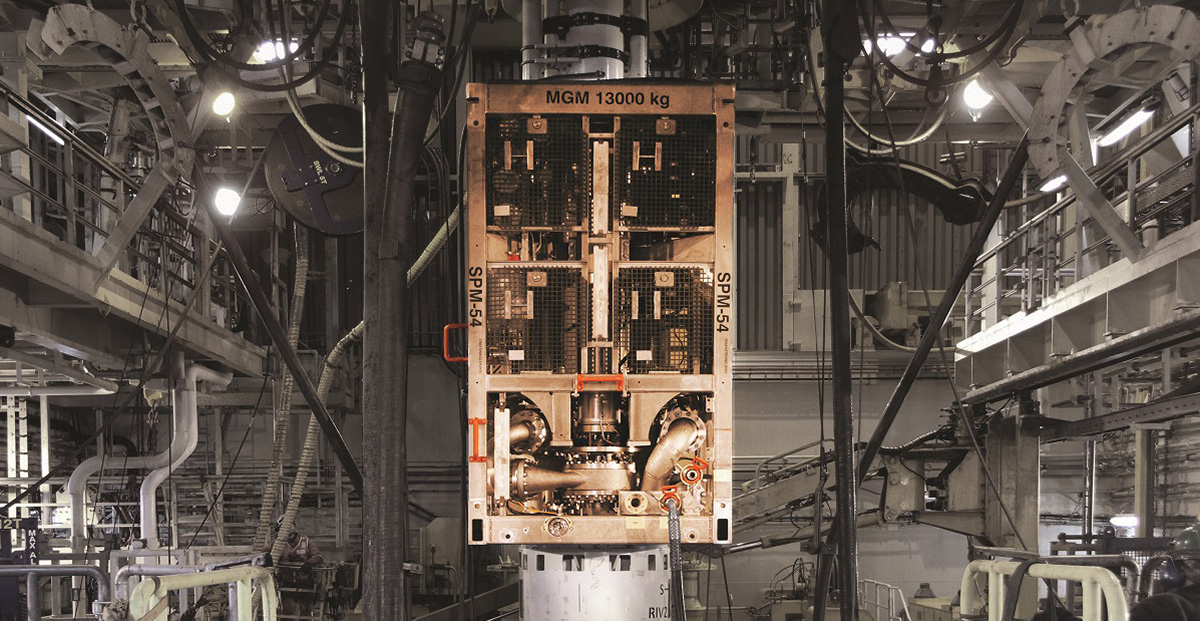

EC-Drill®

EC-Drill® is a Controlled Mud Level (CML) technology that allows manipulation of bottom hole pressure (BHP) while drilling a well.

The system controls the BHP by adjusting the fluid level in the marine drilling riser, and thereby the hydrostatic pressure applied.